Quantum Aerospace Technology is revolutionizing the UAV industry with our heavy-lift hybrid drone that combines extended endurance with high payload capacity, powered by our proprietary generative casting manufacturing process.

Current UAV solutions face significant limitations that prevent widespread adoption across industries requiring heavy-lift capabilities and extended flight times.

Electric UAVs typically offer less than 1 hour of flight time, severely restricting operational range and mission capabilities. Industry average: 45-60 minutes.

Most commercial UAVs can carry less than 100kg, inadequate for many industrial, logistics, and emergency response applications.

Traditional manufacturing methods result in expensive components and limited scalability, keeping prices high and restricting market growth.

QAT's Heavy-Lift Hybrid UAV combines innovative engineering with disruptive manufacturing technology to deliver a revolutionary aerial platform that outperforms existing solutions across all key metrics.

2-3 hours of flight time with full payload capacity, more than double the industry average, enabling longer missions and greater operational range.

Up to 241.3kg (532 lbs) payload capacity, enabling a wide range of applications from heavy cargo transport to firefighting equipment deployment.

Our proprietary generative casting process reduces manufacturing costs by 70-90% compared to traditional methods while improving structural performance.

Combines electric motors with a fuel-powered generator for optimal efficiency, extended range, and reduced environmental impact.

Quickly adaptable to different mission requirements with interchangeable payload systems and sensor packages.

Multiple flight modes from manual to fully autonomous operation with obstacle avoidance and mission planning capabilities.

Triple redundancy in critical systems ensures reliability and safety even in challenging operational environments.

Designed to operate in adverse weather conditions including high winds, rain, and extreme temperatures.

Real-time monitoring and diagnostics capabilities for proactive maintenance and operational optimization.

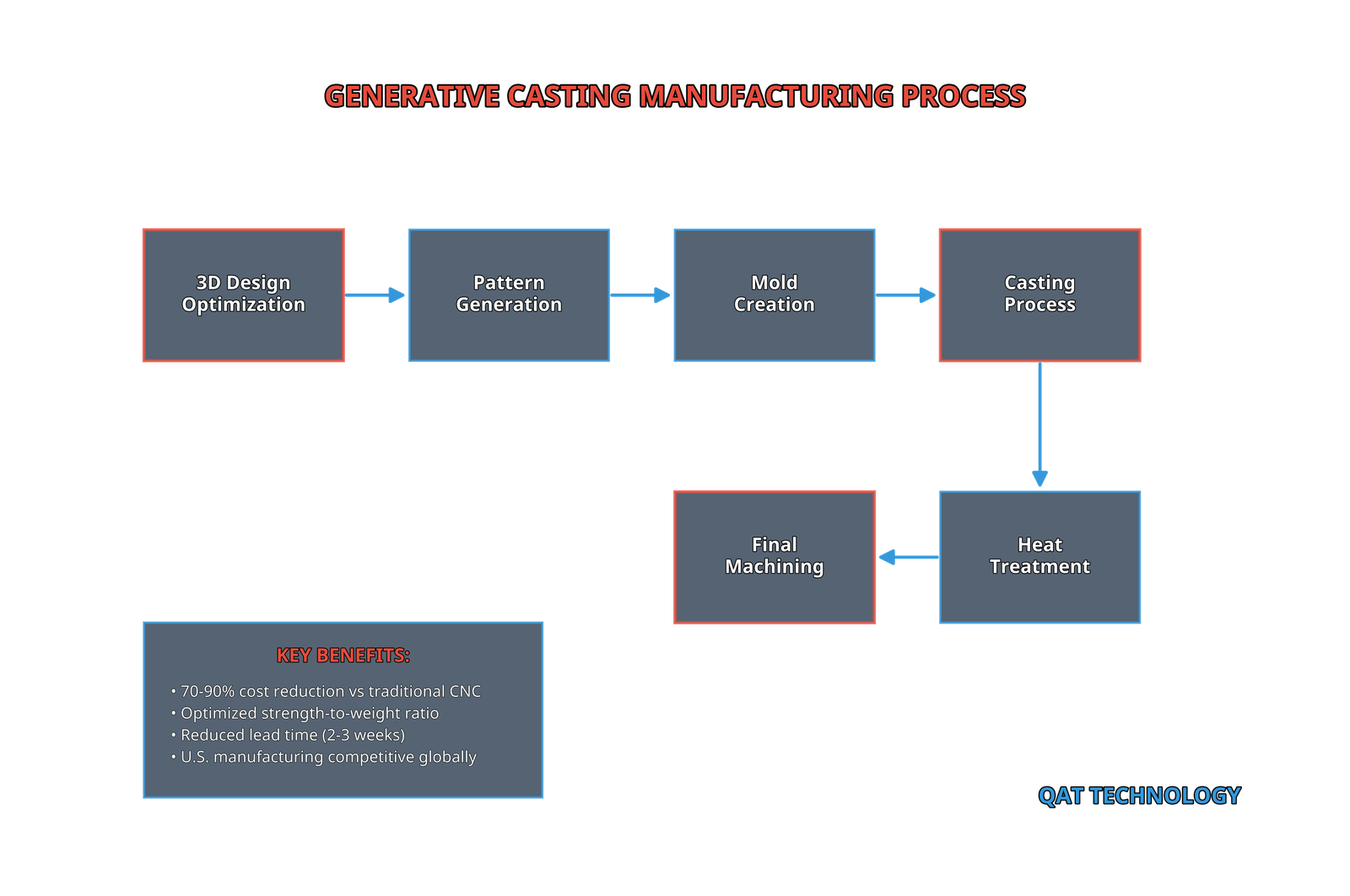

Our proprietary generative casting manufacturing process represents a paradigm shift in aerospace component production, enabling us to create complex, high-performance parts at a fraction of the cost of traditional methods.

Dramatically lower manufacturing costs compared to traditional CNC machining, making high-performance UAVs economically viable at scale.

Generative design algorithms create optimized geometries impossible to achieve with traditional manufacturing, improving strength-to-weight ratio.

Production time reduced from months to weeks, enabling faster iteration, development cycles, and time-to-market.

Our process makes U.S.-based manufacturing economically competitive globally, ensuring supply chain security and quality control.