Our Heavy-Lift Hybrid UAV combines cutting-edge engineering with disruptive manufacturing processes to deliver unprecedented performance, efficiency, and cost-effectiveness.

QAT's Heavy-Lift Hybrid UAV represents a convergence of multiple technological innovations that together create a platform with capabilities far beyond current market offerings.

Our technology stack combines hybrid propulsion systems, generative design principles, advanced materials, and disruptive manufacturing processes to deliver a UAV that outperforms competitors across all key metrics while maintaining a competitive price point.

The result is a versatile aerial platform capable of carrying payloads up to 241.3kg (532 lbs) for 2-3 hours, opening up applications previously impossible with conventional UAV technology.

Explore Our Technologies

Our proprietary hybrid propulsion system combines the best aspects of electric and combustion technologies, delivering extended flight times with high payload capacity while maintaining operational efficiency.

The system uses electric motors for propulsion, powered by a combination of high-density batteries and an onboard fuel-powered generator. This configuration provides the instant torque and precise control of electric systems with the energy density and quick refueling capabilities of combustion engines.

The hybrid system also provides redundancy, as the UAV can operate on battery power alone for short periods if needed, enhancing safety and reliability in mission-critical applications.

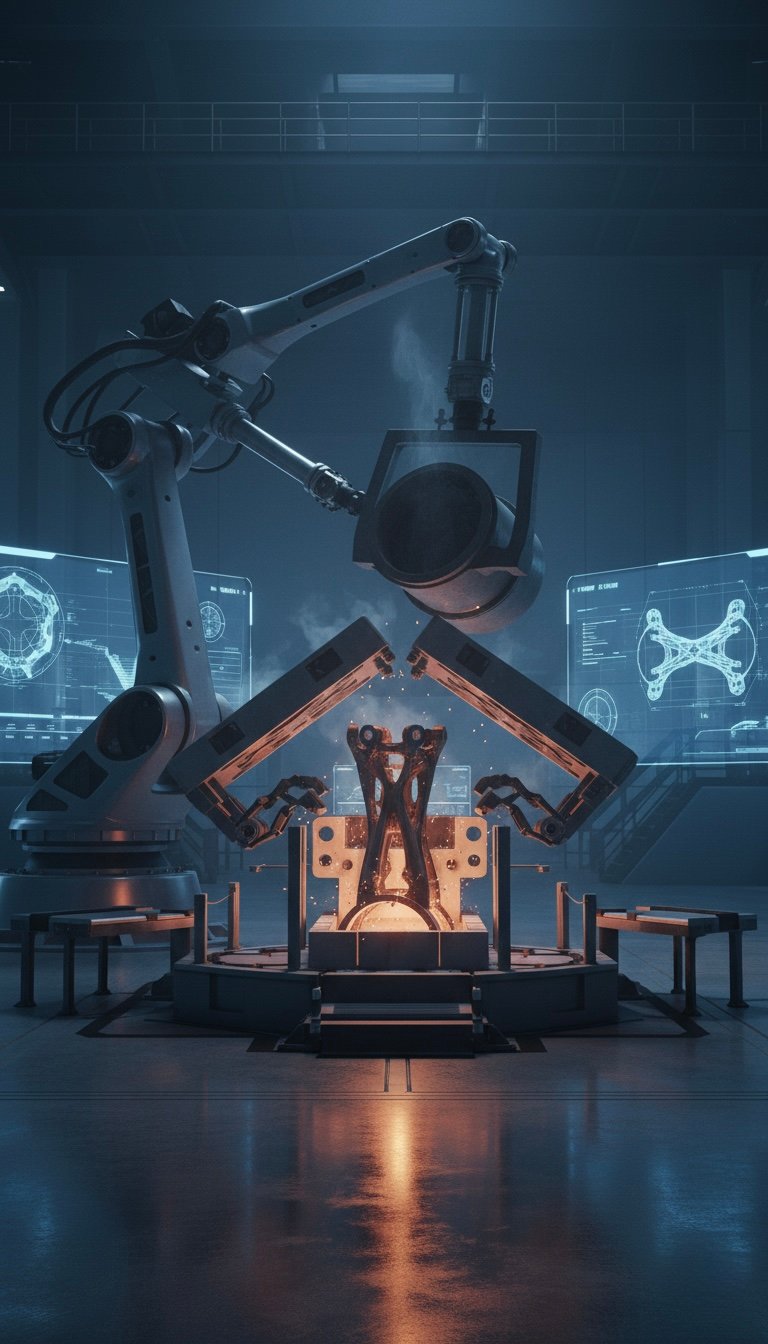

Generative design represents a paradigm shift in how we approach engineering challenges. Rather than traditional design methods where engineers manually create and iterate on designs, our generative approach uses advanced algorithms to explore thousands of possible solutions simultaneously.

By defining performance requirements, constraints, and manufacturing methods, our software generates optimized structures that would be impossible to conceive using conventional design approaches. The result is components with superior strength-to-weight ratios, optimized material distribution, and enhanced performance characteristics.

Engineers specify performance requirements, material constraints, and manufacturing methods.

AI-powered algorithms explore thousands of design possibilities, applying evolutionary principles.

Each design iteration undergoes rigorous structural, aerodynamic, and thermal simulation.

The best designs are further refined based on performance metrics and manufacturing constraints.

Final designs are optimized specifically for our generative casting process, ensuring manufacturability.

Our proprietary Generative Casting process represents a revolutionary approach to manufacturing complex aerospace components. By combining generative design with advanced casting techniques, we've created a manufacturing method that delivers exceptional performance at a fraction of the cost of traditional processes.

Unlike conventional CNC machining that removes up to 90% of raw material to create parts, our process uses 3D-printed patterns to create precision molds, allowing us to cast near-net-shape components that require minimal finishing. This approach dramatically reduces material waste, energy consumption, and production time.

Dramatically lower manufacturing costs compared to traditional CNC machining, making high-performance UAVs economically viable at scale.

Ability to produce complex internal structures and organic shapes that would be impossible or prohibitively expensive with traditional manufacturing.

Our process allows for the use of high-performance alloys with excellent strength-to-weight ratios and fatigue resistance.

Production time reduced from months to weeks, enabling faster iteration, development cycles, and time-to-market.

The economics of our generative casting process create a compelling competitive advantage that translates directly to our ability to offer superior UAVs at competitive price points.

Traditional aerospace manufacturing relies heavily on CNC machining, which involves cutting away up to 90% of raw material blocks to create components. This approach is not only wasteful but extremely expensive, with high material costs, long machining times, and significant energy consumption.

Our generative casting process fundamentally changes this equation by:

Near-net-shape casting requires minimal material removal, reducing raw material costs by up to 80%.

Automated processes and reduced machining time cut labor requirements by 60-70%.

Cost efficiencies make U.S.-based manufacturing economically competitive with offshore alternatives.

| Performance | |

| Maximum Payload | 241.3 kg (532 lbs) |

|---|---|

| Flight Endurance (Max Payload) | 2 hours |

| Flight Endurance (Reduced Payload) | 3+ hours |

| Maximum Range | 100+ km |

| Maximum Speed | 120 km/h (75 mph) |

| Cruise Speed | 80 km/h (50 mph) |

| Maximum Altitude | 3,000 m (9,840 ft) |

| Physical | |

| Dimensions (L×W×H) | 4.77 m × 4.77 m × 1.5 m (15.65 ft × 15.65 ft × 4.92 ft) |

| Dimensions Folded (L×W×H) | 2.10 m × 2.10 m × 1.5 m (6.89 ft × 6.89 ft × 4.92 ft) |

| Empty Weight | 250 kg (551.2 lbs) |

| Maximum Takeoff Weight | 1000 kg (2204.62 lbs) |

| Payload Capacity | 217 - 241 kg (478.4 - 531.3 lbs) |

| Propulsion | 8 × Electric Motors with Hybrid Power System |

| Fuel Capacity | Up to 100L |

| Control & Navigation | |

| Control Modes | Manual, Assisted, Autonomous, Return-to-Launch, Position Hold |

| Navigation System | GPS/GLONASS/Galileo with RTK precision |

| Obstacle Avoidance | 360° LiDAR + Computer Vision |

| Communication Range | Line of sight: 10+ km, Satellite: Global |

| Redundancy | Triple redundant flight controllers and sensors |

| Environmental | |

| Operating Temperature | -20°C to +50°C (-4°F to 122°F) |

| Wind Resistance | Up to 45 km/h (28 mph) sustained |

| Weather Rating | IP54 (Protected against dust and water splashes) |